Making a concrete block machine can be a great business opportunity if you have an interest in concrete products and manufacturing.

Here are some steps to get started:

Research: Conduct research on the concrete block manufacturing industry to gain a better understanding of the different types of machines available and the demand for concrete blocks in your area.

Create a Business Plan: Develop a business plan that outlines your vision for your concrete block machine business. This should include details such as your target market, marketing strategy, production capacity, and startup costs.

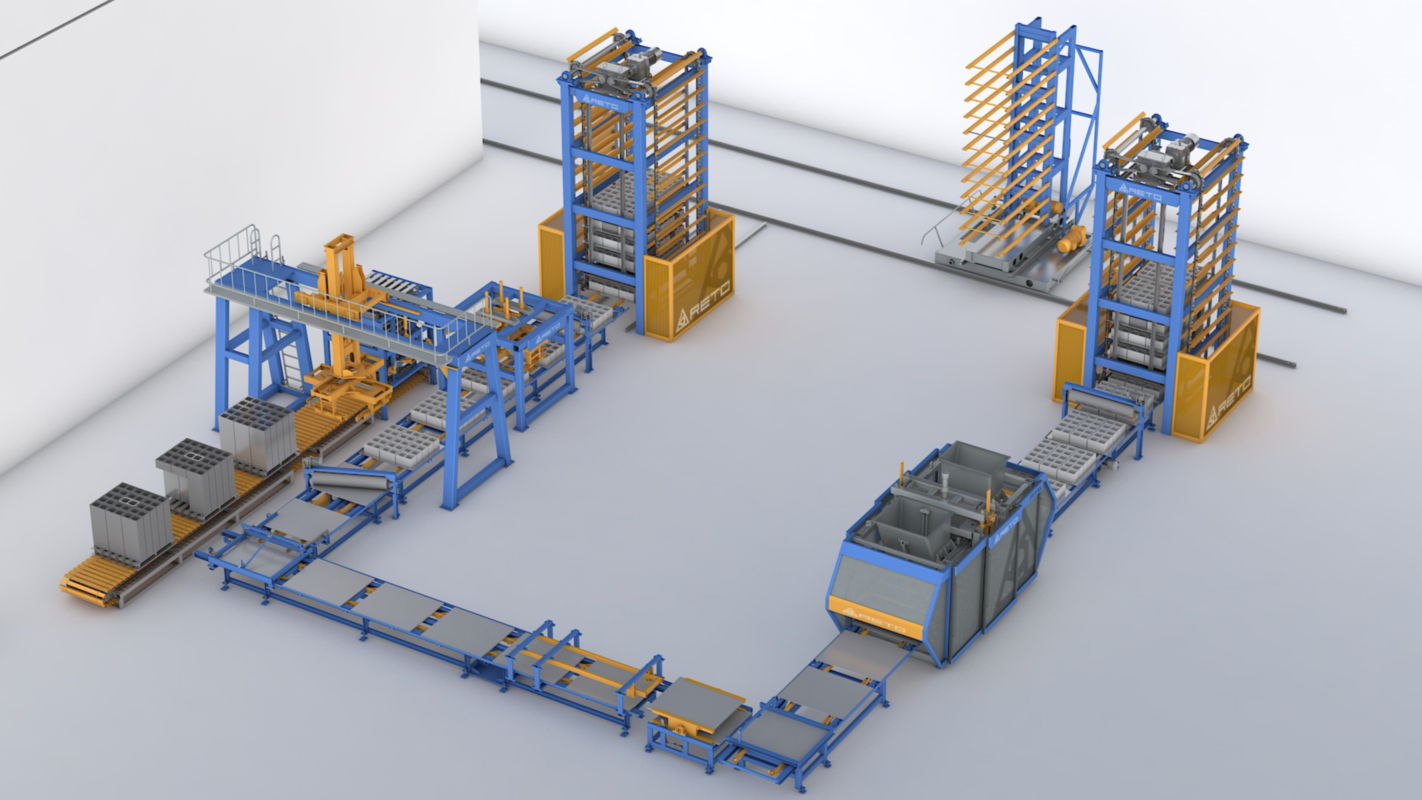

Choose the Right Machine: Select the right type of concrete block machine based on your production needs and budget. There are different types of machines available, including manual, semi-automatic, and fully automatic machines.

Source Materials: Source high-quality materials for your concrete block production, such as cement, sand, and aggregate. Consider purchasing locally sourced materials to reduce transportation costs and support the local economy.

Hire Skilled Workers: Hire skilled workers to operate the machine and handle other aspects of production, such as quality control and packaging.

Market Your Business: Develop a marketing strategy to promote your concrete block machine business. Consider creating a website, attending trade shows, building blocks machine and leveraging social media platforms to reach potential customers.

Scale Up: As your business grows, consider scaling up your production capacity by investing in additional machines or expanding your product line.

Starting a concrete block machine business can be a profitable and rewarding venture if done correctly. By following these steps and committing to producing high-quality products, you can establish a successful concrete block manufacturing business.

How can I ensure the quality of my concrete blocks?

Ensuring the quality of your concrete blocks is crucial to the success of your concrete block manufacturing business.

Here are some tips for ensuring the quality of your concrete blocks:

Quality Control: Implement a quality control program to monitor the quality of your concrete blocks during production. This should include regular testing of the raw materials, as well as inspection of finished blocks to ensure they meet specified standards.

Consistent Mix: Ensure that the concrete mix is consistent and of high quality. Use high-quality materials and ensure that the mix is properly proportioned to achieve the desired strength and durability.

Proper Curing: Proper curing is essential for the strength and durability of your concrete blocks. Ensure that the blocks are cured for the appropriate amount of time and under the right conditions to allow for proper hydration and strength development.

Testing: Conduct regular testing of your concrete blocks to ensure that they meet industry standards for strength, durability, and other quality parameters.

Proper Storage: Store your concrete blocks properly to prevent damage and ensure that they maintain their strength and durability over time. Store them in a dry, well-ventilated area that is free from moisture and other contaminants.

Skilled Workers: Ensure that your workers are skilled and properly trained in the production process to ensure that they produce high-quality concrete blocks.

Continuous Improvement: Continuously monitor and improve your production process to ensure that you are producing the highest quality concrete blocks possible. This may include investing in new equipment or technologies, improving your quality control program, or optimizing your mix design.

By following these tips and committing to producing high-quality concrete blocks, you can establish a strong reputation for your business and attract repeat customers.